Compact Water WK3 (IM160E) Stock unit - Immediatley available !

Stock unit - Immediately available !

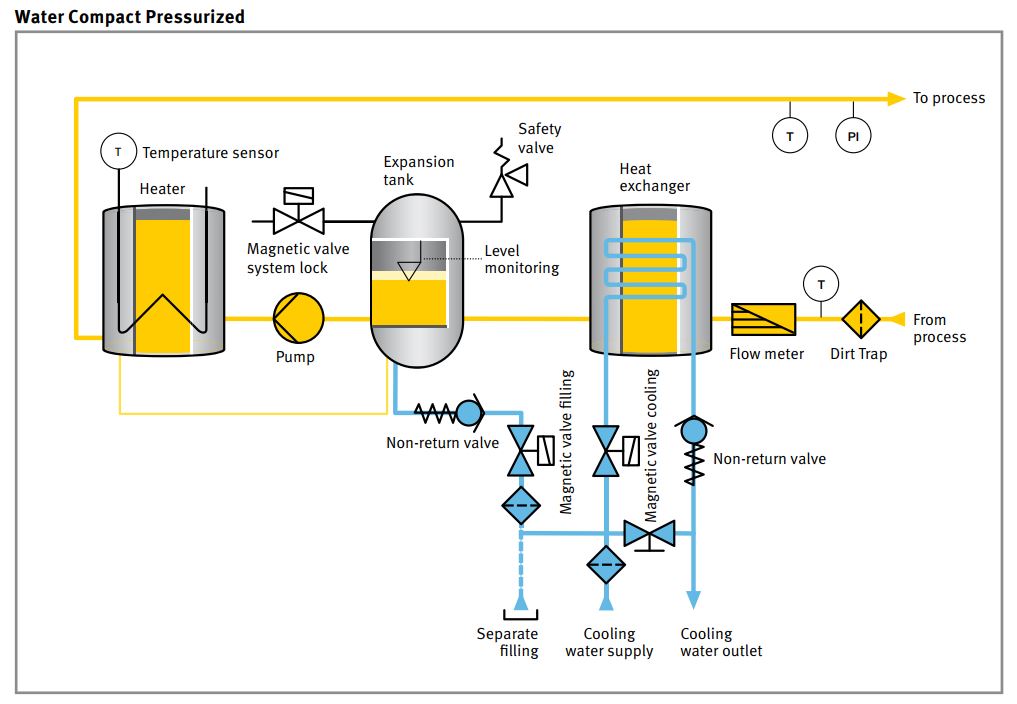

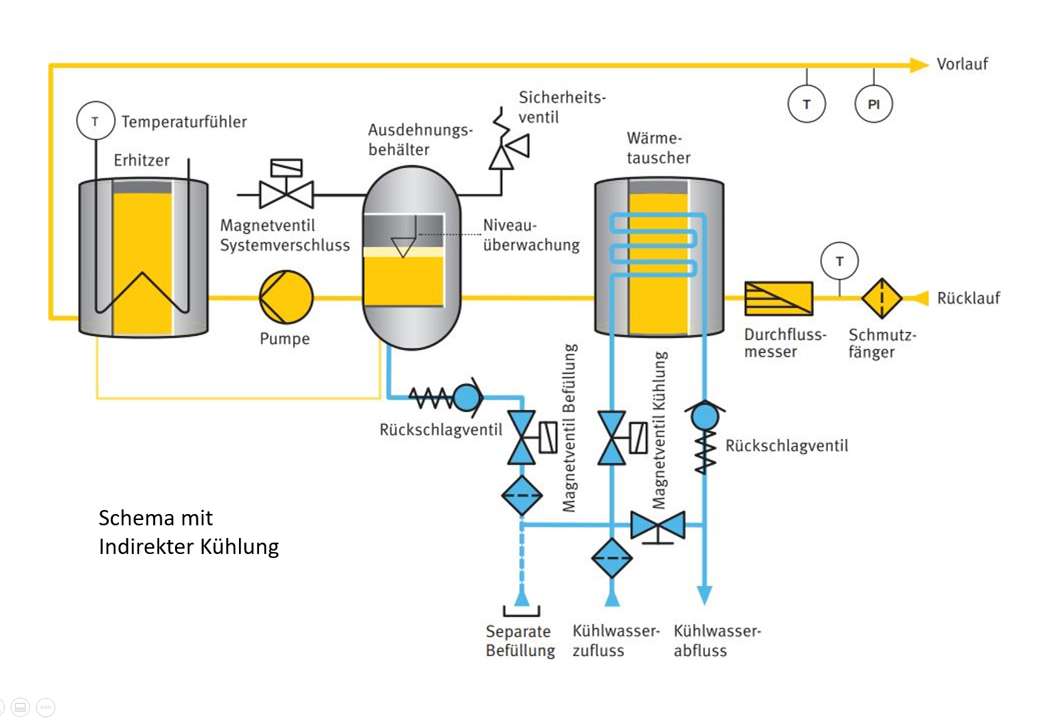

The compact water temperature control system WK3 IM160E is designed for applications and requirements in the small to medium performance range isparticularly common in plastic injection molding, but also in other processes in use. They are suitable for temperature control of high-quality applications and allow documentation of process parameters.

Compared to heat transfer oil, water as a circulating medium offers numerous physical and economic advantages - especially at higher operating temperatures. For example, water has a much better heat transfer performance than oil: its high specific heat capacity is not even approached by any other liquid. Water as a temperature control medium also offers many advantages from an ecological point of view.

The WK3 sizes of the Water Compact product family are designed for operation well above the atmospheric boiling point. They meet the highest safety requirements. The systems are extremely compact and consist exclusively of high-quality components.

- Smart & cost-effective pressurized-vessel solution for applications up to 160 °C. High efficiency and very low energy losses by full isolation of heating carrying parts and optionally speed controlled pumps

- High reliability and availability due to ingenious and robust design using corrosion-free material. IP54 (hydraulic section as well as cabinet) design. Heaters controlled by solid state relais.

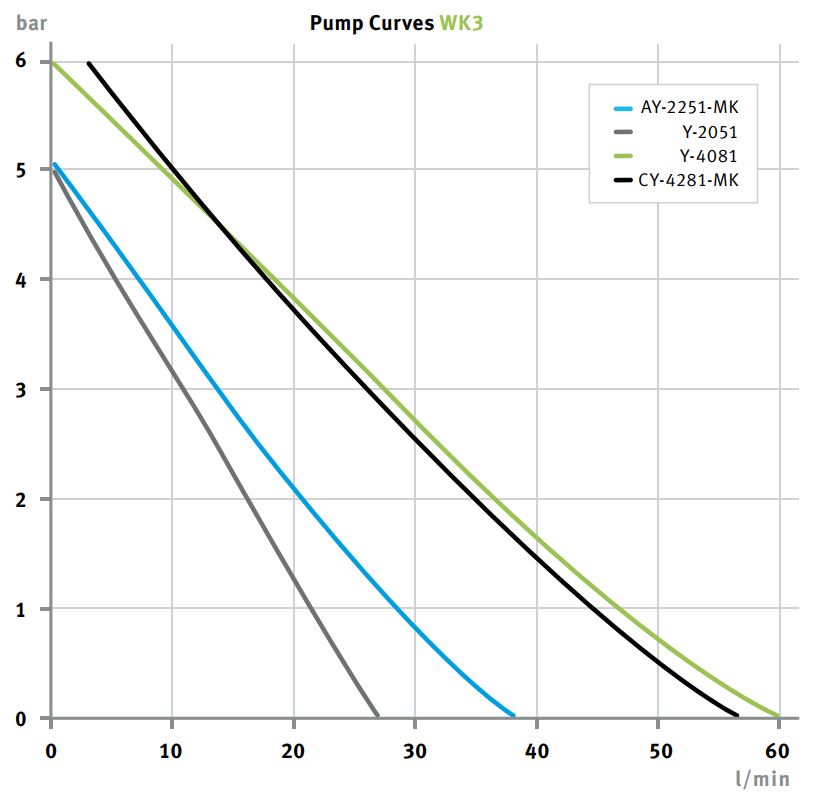

- From 160 °C a robust magnetically coupled pump is available

- German-engineered and manufactured

- State-of-the-art 3,5" touch controller SBC–T with broad range of optional machine-interfaces.

- Compact unit offering highest cooling power capability in their class. Robust stainless-steel pressure-vessel-design construction helps reduce corrosion issues caused by regular efills

- Available with many features and options. Modularized archicecture allows upgrades

- Booster pump to increase the make-up pressure

- Pressure gauge on the supply line

- Suction tool drain

- Suction of the external consumer

- Power interface 20mA Arburg via 9-pin D-Sub

- Connector 16 A plug

- CEE completely mounted

- SBC-T plus controller

- Flow measurement

| File | Category | Size | Filetype |

|---|---|---|---|

| WK3 IM160E Datenblatt | Produkt-Downloads | 59.03 KB |

The illustrations and drawings, size, weight, consumption, performance, chemical and physical data are always approximate.