Used units

Used equipment in top condition

We offer here high quality equipment from our trade show exhibits and rental equipment pool. These units are available in various performance classes and all are in excellent condition with low operating hours. Prior to shipment, our temperature control units are carefully inspected to ensure they are in proper working order.

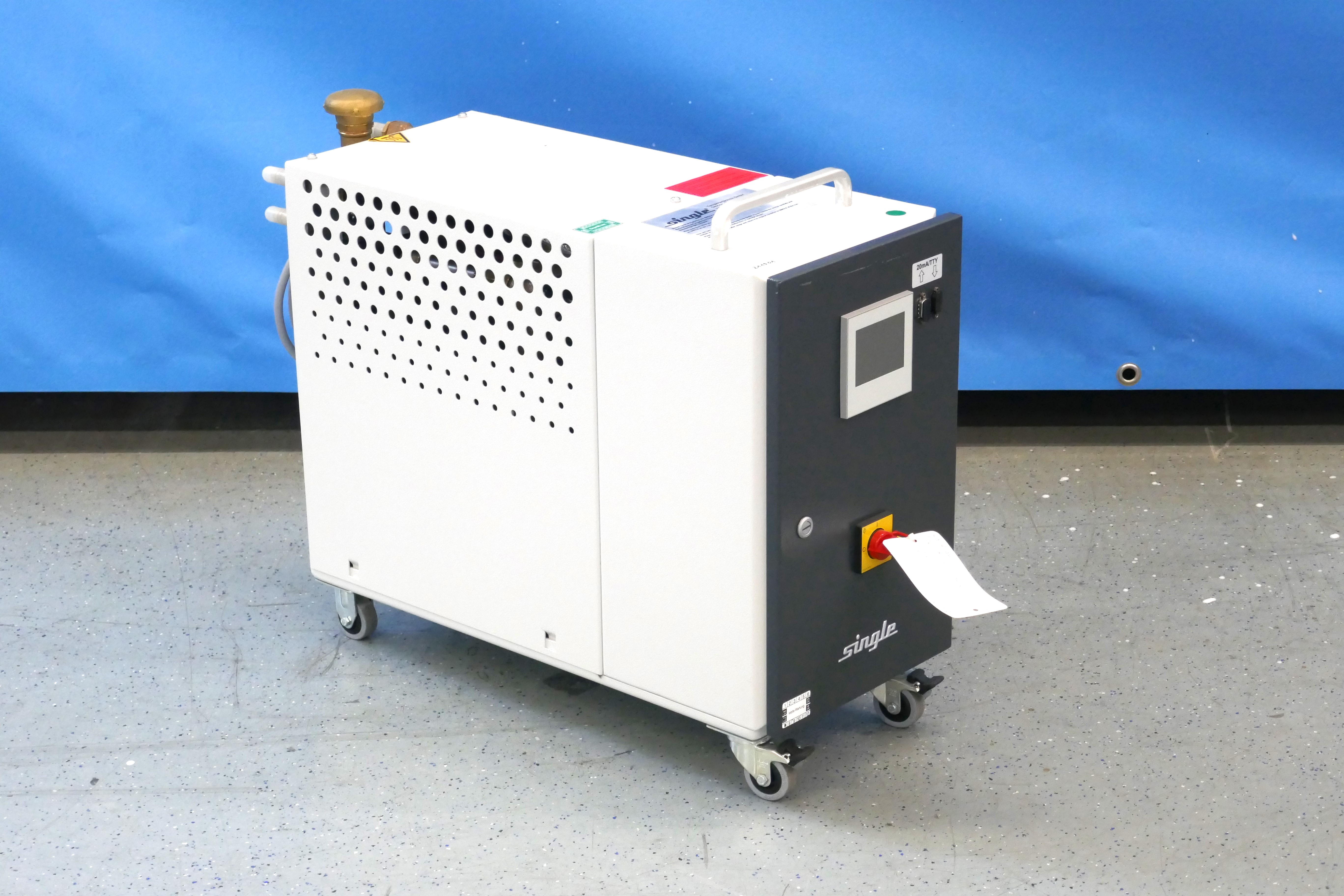

Gebraucht WM3 150-6-45 SN212483

Modell: WM3 150-6-45

Typ: Messegerät

Baujahr: 2021

Seriennummer: 212483

TECHNISCHE DATEN

Temperatur: 150 °C

Medium: Wasser

Heizleistung: 6 kW

Kühlleistung: 45 kW

Förderleistung max.: 27 l/min

Förderdruck max.: 5 bar

Abmessungen: 625 mm x 240 mm x 490 mm

Gewicht: 55 kg

AUSSTATTUNG

Funktionsausstattung hydraulisch:

·

Bypass zwischen Vor- und Rücklauf mit

reduziertem Querschnitt

·

Niveauüberwachung durch Magnet-Schwimmerschalter

·

Schmutzfänger im Kühlwasserzufluss und im

Rücklauf des

·

Umlaufsystems

·

Isolierung aller wärmetragenden hydraulischen

Bauteile

·

Automatischer temperaturabhängiger

Systemverschluss

Funktionausstattung elektrisch:

·

Regel- und Steuereinheit SBC-T (3,5"

Touch-Display)

·

Heizungssteuerung Hybrid SSR

·

Schaltkasten IP54

Allgemeine Ausstattung:

·

Korrosionbeständige Bauteile Edelstahl,

Buntmetall

·

Heizung über Edelstahl-Rohrheizkörper aus

Incoloy

·

Absperrventile im Vor- und Rücklauf

Gebraucht WT3 90-4-50 SN231755

Modell: WT3 90-4-50

Typ: Messegerät

Baujahr: 2023

Seriennummer: 231755

TECHNISCHE DATEN

Temperatur: 90 °C

Medium: Wasser

Heizleistung: 4 kW

Kühlleistung: 50 kW

Förderleistung max.: 40 l/min

Förderdruck max.: 3,8 bar

Abmessungen: 715 mm x 265 mm x 563 mm

Gewicht: 55 kg

AUSSTATTUNG

Funktionsausstattung hydraulisch:

·

Kühlung und Befüllung gesteuert über

Magnetventil

·

automatische Befüllung über Kühlwasser (über

separaten Befüllanschluss mit Schmutzfänger, falls ohne Kühlung)·

·

Schmutzfilter im Kühlwasserzufluss und im

Rücklauf des Umlaufsystems

·

Wendeschaltung für Leckstoppbetrieb (entfällt

bei Rücklaufsicherung und

·

Werkzeugentleerung Druckluft)

·

Niveauüberwachung durch Magnet-Schwimmerschalter

Funktionausstattung elektrisch:

·

Regel- und Steuereinheit SBC-T (3,5"

Touch-Display)

·

Heizungssteuerung Hybrid SSR (bis 415V), darüber

SSR

·

Schaltkasten IP54

·

Heizleistung: Siehe Auftragsbestätigung

Allgemeine Ausstattung:

·

Korrosionsbeständige Bauteile (VA,MS)

·

Heizung über Edelstahl-Rohrheizkörper aus

Incoloy

·

Gerät auf Rollen montiert und anschlussfertig

·

Isolierung um Tank und Wärmetauscher geschäumtes

Material

USED Compact WK3 180-9-50 EcoTemp SN 192565

Model: WK3

180-9-50 EcoTemp

Type: Rental

appliance

Year of

construction: 2019

Serial number:

192565

TECHNICAL DATA

Temperature:

180 °C

Medium: Wasers

Heating

capacity: 9 kW

Cooling

capacity: 50 kW

Max. flow rate:

38 l/min

Max. delivery

pressure: 5 bar

Dimensions:

790mm x 305mm x 705mm

Weight: approx.

90 kg

EQUIPMENT

Professional

package

- Smart

Controller plus

- Pressure

transducer

- Frequency

converter

- EcoTemp

- Interface

Arburg / 20mA TTY

USED easitemp 6/150 SN176275

Model: easitemp

6/150

Type: Rental

device

Year of

manufacture: 2017

Serial number:

176275

TECHNICAL DATA

Temperature:

150 °C

Medium: Water

Heating

capacity: 6 kW

Cooling

capacity: 45 kW

Max. flow rate:

27 l/min

Max. delivery

pressure: 4.5 bar

Dimensions:

600mm x 240mm x 430mm

Weight: 40 kg

EQUIPMENT

-

Microprocessor-controlled regulator, digital display, self-optimisation and

many other features

- Ball valve in

the flow

- Level

monitoring via magnetic float switch

- Reversing

circuit for leak-stop operation (via pole-changing plug)

- Cooling via

copper-soldered stainless steel plate heat exchanger and solenoid valve

- Heating via

stainless steel tubular heating element made of Incolloy material

- Dirt filter

in the return of the circulation system

- Automatic

filling via cooling water

- Automatic

temperature-dependent system closure

- Temperature

limiter

-

Corrosion-resistant components (stainless steel/non-ferrous metal)

- Bypass

between flow and return with reduced cross-section

- Robust

powder-coated sheet steel housing

- Control

voltage 230 V

USED Advanced N1/NS 180-9-50 SN 180917

Second-hand Advanced N1/NS 180-9-50 SN 180917

Model: Advanced N1/NS 180-9-50 SN 180917

Type: Rental device

Year of manufacture: 2018

Serial number: 180917

TECHNICAL DATA

Temperature: 180 °C

Medium: Water

Heating capacity: 9 kW

Cooling capacity: 50 kW

Max. flow rate: 75 l/min

Max. delivery pressure: 3.9 bar

Dimensions: 790mm x 345mm x 945

Weight: 116 kg

EQUIPMENT

- SCT controller

- PT100 temperature sensor

- Frequency converter for pump

- Pressure sensor

- RS 485 interface (9-pin)

- Flow measurement

- Separate automatic filling

- Heating control via solid state relay

- Stainless steel tubular heating element made of Incoloy

Used Advanced NS 150-12-50 SN181434

Model: Advanced

NS 150-12-50

Type: Rental

machine

Year of

manufacture: 2018

Serial number:

181434

TECHNICAL DATA

Temperature:

150 °C

Medium: Water

Heating

capacity: 12 kW

Cooling

capacity: 50 kW

Max. flow rate:

140 l/MIN

Max. delivery

pressure: 4.0 bar

Dimensions:

790mm x 345mm x 945mm

Weight: 140 kg

EQUIPMENT

- SCT

controller

- Flow

measurement

- Automatic

filling

- Heating

control via solid state relay

- Stainless steel

tubular heating element made of incoloy

Used Advanced NS 150-12-50 SN181435

Model: Advanced

NS 150-12-50

Type: Rental

machine

Year of

manufacture: 2018

Serial number:

181435

TECHNICAL DATA

Temperature:

150 °C

Medium: Water

Heating

capacity: 12 kW

Cooling

capacity: 50 kW

Max. flow rate:

140 l/min

Max. delivery

pressure: 4.0 bar

Dimensions:

790mm x 345mm x 945mm

Weight: 140 kg

EQUIPMENT

- SCT

controller

- Flow

measurement

- Automatic

filling

- Heating

control via solid state relay

- Stainless steel

tubular heating element made of Incoloy

Used Advanced WP5 90-46-220 SN202357

Model:

WP5 90-46-220 SN202357

Type:

Rental unit

Year

of manufacture: 2020

Serial

number: 202357

TECHNICAL

DATA

Temperature:

90 °C

Medium:

Water

Heating

capacity: 48 kW

Cooling

capacity: 220 kW

Max.

flow rate: 73 l/min

Max.

delivery pressure: 7.5 bar

Dimensions:

1465 mm x 485 mm x 1090 mm

Weight:

160 kg

EQUIPMENT

-

Basic package

-

SBC-T controller

-

More powerful pump

-

Flow measurement

-

Heating control via solid state relay

USED Compact K 160-9-24 SN171854

Model: Compact K 160-9-24

Type: Fair unit

Year of manufacture: 2017

Serial number: 171854

TECHNICAL DATA

Temperature: 160 °C

Medium: Water

Heating capacity: 9 kW

Cooling capacity: 24 kW

Max. flow rate: 30 l/min

Max. delivery pressure: 5 bar

Dimensions: 739mm x 276mm x 772mm

Weight: 61kg

EQUIPMENT

- SBC-T controller

- Boosted pump

- Integrated water make-up

- 9 pole / 20 mA/TTY

- Tool draining

- 16 A plug

Used Compact K/KN 180-6-42 SN181755

Model: Compact

K/KN 180-6-42

Type: Rental

machine

Year of

manufacture: 2018

Serial number:

181755

TECHNICAL DATA

Temperature:

180 °C

Medium: Water

Heating

capacity: 6 kW

Cooling

capacity: 42 kW

Max. flow rate:

40 l/min

Max. delivery

pressure: 5.0 bar

Dimensions:

741mm x 276mm x 733mm

Weight: 75 kg

EQUIPMENT

- Smart

Controller

- PT100

temperature sensor

- Return

temperature display

- Flow

measurement

- Profibus DP

(9-pin connector)

Used Compact Oil DM250-6-14

Model: Compact Oil 250-6-14

Type: Rental machine

Year of construction: 2017

Serial number: 172829

TECHNICAL DATA

Temperature: 250 °C

Medium: Oil

Heating capacity: 6 kW

Cooling capacity: 14 kW

Max. flow rate: 60 l/min

Max. delivery pressure: 6 bar

Dimensions: 609mm x 254mm x 547mm

Weight : 75 kg

EQUIPMENT

- SBC-T controller

- 9 pole / 20 mA/TTY interface

- Flow measurement

- Mould draining

- Temperature sensor PT 100

- Frequency converter for pump

- Pressure sensor in the flow

- Cooling water bypass 4mm

- 16A plug

Used Compact TK 90-6-24 SN202143

Model: Compact

TK 90-6-24

Type: Rental

unit

Year of

manufacture: 2020

Serial number:

202143

TECHNICAL DATA

Temperature: 90

°C

Medium: Water

Heating

capacity: 6 kW

Cooling

capacity: 24 kW

Max. flow rate:

40 l/min

Max. delivery

pressure: 3.8 bar

Dimensions:

639mm x 266mm x 562mm

Weight: 50 kg

EQUIPMENT

- SBC-T plus

controller

- Backflow

protection

- Overflow

valve

- Flow

measurement

Used Compact WK3 150-4-50 SN 202245

Model: WK3

150-4-50

Type: Rental

unit

Year of

manufacture: 2021

Serial number:

202245

TECHNICAL DATA

Temperature:

150 °C

Medium: Water

Heating

capacity: 4 kW

Cooling

capacity: 50 kW

Max. flow rate:

60 l/min

Max. delivery

pressure: 6.0 bar

Dimensions: 760

mm x 305 mm x 835 mm

Weight: approx.

90 kg

EQUIPMENT

- Advanced

package

- Smart

Controller

- PT100

temperature sensor

- More powerful

pump

- Backflow

protection

Used easitemp 6/150 SN 200754

Model: easitemp 6/150

Type: Rental device

Year of manufacture: 2020

Serial number: 200754

TECHNICAL DATA

Temperature: 150 °C

Medium: Water

Heating capacity: 6 kW

Cooling capacity: 45 kW

Max. flow rate: 27 l/min

Max. delivery pressure: 4.5 bar

Dimensions: 600mm x 240mm x 430mm

Weight: 40 kg

EQUIPMENT

- Microprocessor-controlled regulator, digital display,

self-optimization and many other features

- Ball valve in the flow

- Level monitoring by magnetic float switch

- Reversing circuit for leak-stop operation (via

pole-changing plug)

- Cooling via copper-soldered stainless steel plate heat

exchanger and solenoid valve

- Heating via stainless steel tubular heating element made

of Incoloy

- Dirt filter in the return of the circulation system

- Automatic filling via cooling water

- Automatic temperature-dependent system closure

- Temperature limiter

- Corrosion-resistant components (stainless

steel/non-ferrous metal)

- Bypass between flow and return with reduced cross-section

- Robust powder-coated sheet steel housing

- Control voltage 230 V

Used TK 90-9-50 SN182152

Model: TK 90-9-50

Type: Rental machine

Year of manufacture: 2018

Serial number: 182152

TECHNICAL DATA

Temperature: 90 °C

Medium: Water

Heating capacity: 9 kW

Cooling capacity: 50 kW

Max. flow rate: 58 l/min

Max. delivery pressure: 5.2 bar

Dimensions: 639 mm x 266 mm x 562 mm

Weight: approx. 50 kg

EQUIPMENT

- SBC-Tplus controller

- Flow measurement

- Suction mould emptying (M.TDS.TK)

- Suction of the external consumer

- 16 A plug / CEE completely mounted (E.PSC16.TK)

- Current interface 20mA TTY; protocol selectable Arburg,Engel KraussMaffei,Bühler,Dr.Boy Single via 9-pin D-Sub connector (SBC-T.IFTTY) Engel

Used TK 90-9-50 SN211901

Model: TK

90-9-50

Type: Rental

unit

Year of

manufacture: 2021

Serial number:

211901

TECHNICAL DATA

Temperature: 90

°C

Medium: Water

Heating

capacity: 9 kW

Cooling

capacity: 50 kW

Max. flow rate:

54 l/min

Max. delivery

pressure: 6.0 bar

Dimensions: 639

mm x 266 mm x 562 mm

Weight: 50 kg

EQUIPMENT

- SBC-T

controller

- More powerful

pump

- Interface 20

mA/TYY 9-pin (Arburg assignment)

- Tool emptying

- 16 A plug

USED TKS 90-36-116 SN180661

Model: TKS 90-36-116

Type: Rental machine

Year of construction: 2018

Serial number: 180661

TECHNICAL DATA

Temperature: 90 °C

Medium: Water

Heating capacity: 36 kW

Cooling capacity: 116 kW

Max. flow rate: 135 l/min

Max. delivery pressure: 5.6 bar

Dimensions: 895mm x 356mm x 873mm

Weight: approx. 100 kg

EQUIPMENT

- SBC-T controller

- 9-pin / 20mA interface

- Temperature sensor PT100

- Flow measurement

- Amplified pump

- Frequency converter for pump

- Pressure sensor in the flow